获取优惠价格

Tel:18790282122矿渣的处理方法

矿山矿渣的处理方法是什么?

对矿渣采用高细粉磨的方式加以处理是目前综合利用中常见的工艺,矿渣原料由铲车取料、喂料,通过皮带机进行输送。在输送过程中,矿渣原料先后经由除铁器和振动筛除铁和筛分,然后通过提升机进入雷蒙磨粉机进行粉磨。矿渣的处理方法. 本发明在短时间内以高效且低成本地对制钢矿渣等进行老化处理。. 具有对制钢矿渣等高温矿渣进行洒水的工序 (A),以及通过将因工序 (A)中的洒水而产生的蒸汽与 矿渣的处理方法_百度文库

查看更多

走出“一无是处”的尴尬!工业固废再利用系列

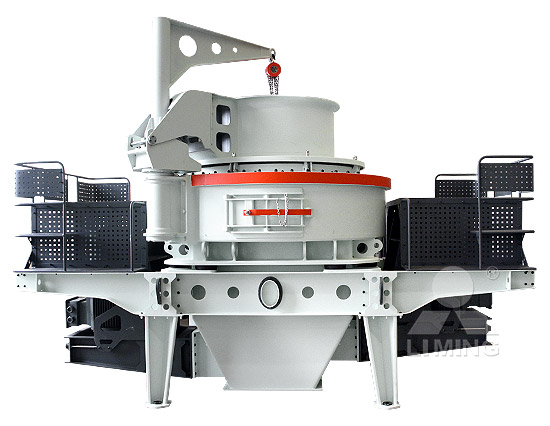

1、破碎设备 矿渣需破碎之后用于道路基层或垫层,常用的破碎设备有:反击式破碎机、对辊式破碎机、圆锥式破碎机以及矿渣移动破碎站等。 2、磨粉设备 矿渣微粉作为高性能混凝土的新型掺合料,具有改善混凝土抗压、抗 然而,高炉矿渣的处理方法不只有填埋和焚烧。尽管这两种方法在某些情况下可能适用,但填埋易造成环境污染,焚烧则会产生二次污染。为了更好地实现环保和 高炉矿渣的处理和利用 豆丁网

查看更多

矿业固体废物_百度百科

矿业固体废物简称矿业废物指开采和洗选矿石过程中产生的废石和尾矿。矿石开采过程中,需剥离围岩,排出废石,采得的矿石亦需经洗选,提高品位,排出尾矿。对环境的危害: 钢渣处理工艺流程湿法处理步骤:. 步骤一:钢渣的破碎和磨矿。. 一般钢厂生产的钢渣都呈规则不均匀的块状,钢粒、铁粉和渣子都混合在一起,如果要把钢粒和铁粉从大块渣子中分离开,就必须先破碎、研磨,打破它们 钢渣处理工艺流程简介

查看更多

选矿厂产生的尾矿都有哪些利用方法?

4. 矿渣处理方法. 矿渣是从冶金反应中产生的固体残渣,通常是由氧化物、硅酸盐、钙和镁等元素组成。处理矿渣的方法因其成分和性质而异。以下是几种处理矿渣的常用方法: 5. US6250109B1 US09/180,888 US18088899A US6250109B1 US 6250109 B1 US6250109 B1 US 6250109B1 US 18088899 A US18088899 A US 18088899A US 6250109 B1 US6250109 B1 US 6250109B1 Authority US United States Prior art keywords slag cooling cooling roll plates distributing channel Prior art date Legal status (The legal US6250109B1 Method of continuously producing vitreous blast

查看更多

KR20130099102A 철 슬랙의 건식 입상화 Google Patents

가열 액상 슬랙의 건식 입상화 공정에 있어서, 가열 액상 슬랙이 고형 금속 입자와 혼합되어, 상기 금속 입자와 혼합된 고형화된 유리화(vitrified) 슬랙 케이크를 형성하며, 상기 슬랙 케이크는 가열 슬랙 입자 및 가열된 고형 입자를 형성하도록 파쇄되고, 상기 입자들은 냉각되며, 상기 고형 금속WO2012034897A2 PCT/EP2011/065351 EP2011065351W WO2012034897A2 WO 2012034897 A2 WO2012034897 A2 WO 2012034897A2 EP 2011065351 W EP2011065351 W EP 2011065351W WO 2012034897 A2 WO2012034897 A2 WO 2012034897A2 Authority WO WIPO (PCT) Prior art keywords slag particles metallic particles solid metallic dry Dry granulation of metallurgical slag Google Patents

查看更多

US6250109B1 Method of continuously producing vitreous blast

US6250109B1 US09/180,888 US18088899A US6250109B1 US 6250109 B1 US6250109 B1 US 6250109B1 US 18088899 A US18088899 A US 18088899A US 6250109 B1 US6250109 B1 US 6250109B1 Authority US United States Prior art keywords slag cooling cooling roll plates distributing channel Prior art date Legal status (The legal CN105414557B CN201510964784.4A CN201510964784A CN105414557B CN 105414557 B CN105414557 B CN 105414557B CN 201510964784 A CN201510964784 A CN 201510964784A CN 105414557 B CN105414557 B CN 105414557B Authority CN China Prior art keywords automatic tank granulation metal overflow Prior art date CN105414557B Google Patents

查看更多

CA2810544A1 Dry granulation of metallurgical slag Google

CA2810544A1 CA 2810544 CA2810544A CA2810544A1 CA 2810544 A1 CA2810544 A1 CA 2810544A1 CA 2810544 CA2810544 CA 2810544 CA 2810544 A CA2810544 A CA 2810544A CA 2810544 A1 CA2810544 A1 CA 2810544A1 Authority CA Canada Prior art keywords slag particles metallic particles solid metallic dry granulation Prior art date 2010 WO2009116684A1 PCT/JP2009/056023 JP2009056023W WO2009116684A1 WO 2009116684 A1 WO2009116684 A1 WO 2009116684A1 JP 2009056023 W JP2009056023 W JP 2009056023W WO 2009116684 A1 WO2009116684 A1 WO 2009116684A1 Authority WO WIPO (PCT) Prior art keywords slag cooling steam processing treatment Prior art WO2009116684A1 スラグの処理方法 Google Patents

查看更多

CN1515350A 将熔融液制成球形颗粒产品的造粒装置

CN1515350A CNA031000118A CN03100011A CN1515350A CN 1515350 A CN1515350 A CN 1515350A CN A031000118 A CNA031000118 A CN A031000118A CN 03100011 A CN03100011 A CN 03100011A CN 1515350 A CN1515350 A CN 1515350A Authority CN China Prior art keywords distribution grid fused solution nozzle tower body product Prior EP2576844A1 EP11721772.9A EP11721772A EP2576844A1 EP 2576844 A1 EP2576844 A1 EP 2576844A1 EP 11721772 A EP11721772 A EP 11721772A EP 2576844 A1 EP2576844 A1 EP 2576844A1 Authority EP European Patent Office Prior art keywords slag cone cooling film lateral surface Prior art date Legal status (The legal status Method and device for manufacturing vitreous Google Patents

查看更多

US6250109B1 Method of continuously producing vitreous blast

US6250109B1 US09/180,888 US18088899A US6250109B1 US 6250109 B1 US6250109 B1 US 6250109B1 US 18088899 A US18088899 A US 18088899A US 6250109 B1 US6250109 B1 US 6250109B1 Authority US United States Prior art keywords slag cooling cooling roll plates distributing channel Prior art date Legal status (The legal EP2576844A1 EP11721772.9A EP11721772A EP2576844A1 EP 2576844 A1 EP2576844 A1 EP 2576844A1 EP 11721772 A EP11721772 A EP 11721772A EP 2576844 A1 EP2576844 A1 EP 2576844A1 Authority EP European Patent Office Prior art keywords slag cone cooling film lateral surface Prior art date Legal status (The legal status Method and device for manufacturing vitreous Google Patents

查看更多

CN103003451A 用于制造玻璃质的方法和设备 Google Patents

CN103003451A CN2011800260412A CN201180026041A CN103003451A CN 103003451 A CN103003451 A CN 103003451A CN 2011800260412 A CN2011800260412 A CN 2011800260412A CN 201180026041 A CN201180026041 A CN 201180026041A CN 103003451 A CN103003451 A CN 103003451A Authority CN China Prior art keywords CN103003451A CN2011800260412A CN201180026041A CN103003451A CN 103003451 A CN103003451 A CN 103003451A CN 2011800260412 A CN2011800260412 A CN 2011800260412A CN 201180026041 A CN201180026041 A CN 201180026041A CN 103003451 A CN103003451 A CN 103003451A Authority CN China Prior art keywords CN103003451A 用于制造玻璃质的方法和设备 Google Patents

查看更多

CA2810544A1 Dry granulation of metallurgical slag Google

CA2810544A1 CA 2810544 CA2810544A CA2810544A1 CA 2810544 A1 CA2810544 A1 CA 2810544A1 CA 2810544 CA2810544 CA 2810544 CA 2810544 A CA2810544 A CA 2810544A CA 2810544 A1 CA2810544 A1 CA 2810544A1 Authority CA Canada Prior art keywords slag particles metallic particles solid metallic dry granulation Prior art date 2010 AU2011257264B2 AU2011257264A AU2011257264A AU2011257264B2 AU 2011257264 B2 AU2011257264 B2 AU 2011257264B2 AU 2011257264 A AU2011257264 A AU 2011257264A AU 2011257264 A AU2011257264 A AU 2011257264A AU 2011257264 B2 AU2011257264 B2 AU 2011257264B2 Authority AU Australia Prior Method and device for manufacturing vitreous Google Patents

查看更多

Method and device for manufacturing vitreous Google Patents

WO2011147883A1 PCT/EP2011/058581 EP2011058581W WO2011147883A1 WO 2011147883 A1 WO2011147883 A1 WO 2011147883A1 EP 2011058581 W EP2011058581 W EP 2011058581W WO 2011147883 A1 WO2011147883 A1 WO 2011147883A1 Authority WO WIPO (PCT) Prior art keywords slag cone cooling film lateral surface Prior art date CN212237171U CN202021622231.3U CN202021622231U CN212237171U CN 212237171 U CN212237171 U CN 212237171U CN 202021622231 U CN202021622231 U CN 202021622231U CN 212237171 U CN212237171 U CN 212237171U Authority CN China Prior art keywords cooling rotary drum granulation cooling water sulfur Prior art date CN212237171U 具有冷却流道的转筒硫磺造粒成套设备

查看更多

Method and device for manufacturing vitreous Google Patents

WO2011147883A1 PCT/EP2011/058581 EP2011058581W WO2011147883A1 WO 2011147883 A1 WO2011147883 A1 WO 2011147883A1 EP 2011058581 W EP2011058581 W EP 2011058581W WO 2011147883 A1 WO2011147883 A1 WO 2011147883A1 Authority WO WIPO (PCT) Prior art keywords slag cone cooling film lateral surface Prior art date TWI393697B TW098108889A TW98108889A TWI393697B TW I393697 B TWI393697 B TW I393697B TW 098108889 A TW098108889 A TW 098108889A TW 98108889 A TW98108889 A TW 98108889A TW I393697 B TWI393697 B TW I393697B Authority TW Taiwan Prior art keywords slag cooling drum molten slag cooling treatment Prior art date TWI393697B A cooling treatment device for melting molten slag

查看更多

CA2800101A1 Method and device for manufacturing vitreous

CA2800101A1 CA2800101A CA2800101A CA2800101A1 CA 2800101 A1 CA2800101 A1 CA 2800101A1 CA 2800101 A CA2800101 A CA 2800101A CA 2800101 A CA2800101 A CA 2800101A CA 2800101 A1 CA2800101 A1 CA 2800101A1 Authority CA Canada Prior art keywords slag cone cooling film lateral surface Prior art date Legal status WO2011147883A1 PCT/EP2011/058581 EP2011058581W WO2011147883A1 WO 2011147883 A1 WO2011147883 A1 WO 2011147883A1 EP 2011058581 W EP2011058581 W EP 2011058581W WO 2011147883 A1 WO2011147883 A1 WO 2011147883A1 Authority WO WIPO (PCT) Prior art keywords slag cone cooling film lateral surface Prior art date Method and device for manufacturing vitreous Google Patents

查看更多

Method and device for manufacturing vitreous Google Patents

WO2011147883A1 PCT/EP2011/058581 EP2011058581W WO2011147883A1 WO 2011147883 A1 WO2011147883 A1 WO 2011147883A1 EP 2011058581 W EP2011058581 W EP 2011058581W WO 2011147883 A1 WO2011147883 A1 WO 2011147883A1 Authority WO WIPO (PCT) Prior art keywords slag cone cooling film lateral surface Prior art date US20130152632A1 US13/699,995 US201113699995A US2013152632A1 US 20130152632 A1 US20130152632 A1 US 20130152632A1 US 201113699995 A US201113699995 A US 201113699995A US 2013152632 A1 US2013152632 A1 US 2013152632A1 Authority US United States Prior art keywords slag cone cooling lateral surface film Prior art date 2010 US20130152632A1 Method and device for manufacturing

查看更多

Procédé de traitement des scories Google Patents

L'invention concerne un procédé efficace, rapide et peu coûteux de vieillissement des scories d'acier et similaire. Le procédé de traitement de scories comprend une étape (A) consistant à pulvériser de l'eau sur des scories à température élevée telles que des scories d'acier, et une étape (B) consistant à faire vieillir les scories en mettant en contact la US6250109B1 US09/180,888 US18088899A US6250109B1 US 6250109 B1 US6250109 B1 US 6250109B1 US 18088899 A US18088899 A US 18088899A US 6250109 B1 US6250109 B1 US 6250109B1 Authority US United States Prior art keywords slag cooling cooling roll plates distributing channel Prior art date Legal status (The legal US6250109B1 Method of continuously producing vitreous blast

查看更多

CN102465188B 罐式冶金熔渣处理装置 Google Patents

CN102465188B CN2010105327295A CN201010532729A CN102465188B CN 102465188 B CN102465188 B CN 102465188B CN 2010105327295 A CN2010105327295 A CN 2010105327295A CN 201010532729 A CN201010532729 A CN 201010532729A CN 102465188 B CN102465188 B CN 102465188B Authority CN China Prior art keywords CN1565715A CN 03137690 CN03137690A CN1565715A CN 1565715 A CN1565715 A CN 1565715A CN 03137690 CN03137690 CN 03137690 CN 03137690 A CN03137690 A CN 03137690A CN 1565715 A CN1565715 A CN 1565715A Authority CN China Prior art keywords fused solution distribution grid nozzle flange tower body Prior art date 2003-06 CN1565715A 一种将熔融液制成球形颗粒的造粒装置

查看更多

CN1212180C 将熔融液制成球形颗粒产品的造粒装置

CN1212180C CN 03100011 CN03100011A CN1212180C CN 1212180 C CN1212180 C CN 1212180C CN 03100011 CN03100011 CN 03100011 CN 03100011 A CN03100011 A CN 03100011A CN 1212180 C CN1212180 C CN 1212180C Authority CN China Prior art keywords nozzle distribution grid tower body fused solution product Prior art date 2003 【課題】冷却ロール方式のスラグ冷却処理装置において冷却・固化した後、未だ高温状態にあるスラグから高い顕熱回収率で顕熱回収を行う。 【解決手段】溶融スラグを回転する冷却ロールの外周面に供給して冷却・固化させた後、この固化したスラグを熱交換用のガスと接触させ、スラグのJP2012001418A スラグの顕熱回収方法 Google Patents

查看更多

US6250109B1 Method of continuously producing vitreous blast

US6250109B1 US09/180,888 US18088899A US6250109B1 US 6250109 B1 US6250109 B1 US 6250109B1 US 18088899 A US18088899 A US 18088899A US 6250109 B1 US6250109 B1 US 6250109B1 Authority US United States Prior art keywords slag cooling cooling roll plates distributing channel Prior art date Legal status (The legal

查看更多- 反击石头破碎机产量40TH

- 广西沙机设备厂

- 制粉工艺流程图

- 碳棒生产工艺

- TBM32型岩石掘进机

- 成都破碎机销售哪里有?

- 购买河卵石制砂机当然要选择环保型的

- 贵州贵阳生石灰鄂式破碎设备

- MK42-65旋回破碎机

- 对辊制砂机哪家好

- 怎么能看透磨砂玻璃

- 重刚玉厂的生产过程

- 日产600方石头制沙机哪种好

- 矿用救护设备

- 长石反击式粗碎机如何提高设备产量

- 铝矾土价格磨粉机设备

- 锂矿石生产技术

- 100TPH冲击式破碎机

- 浦东新区区委委员名单

- 叶腊石破碎机

- 60顿沙子等于多少方

- 水泥构件加工设备主要加工设备

- 花岗岩做道砟石有没有问题

- 火电厂磨煤机,这样对电厂的排放物

- 5X1145煤炭石料整形机

- 1000目石英粉设备

- 建铁选厂可行性研究报告

- 真石英石的价格

- 上海雷蒙磨粉设备

- 辊式粉碎机传动原理图